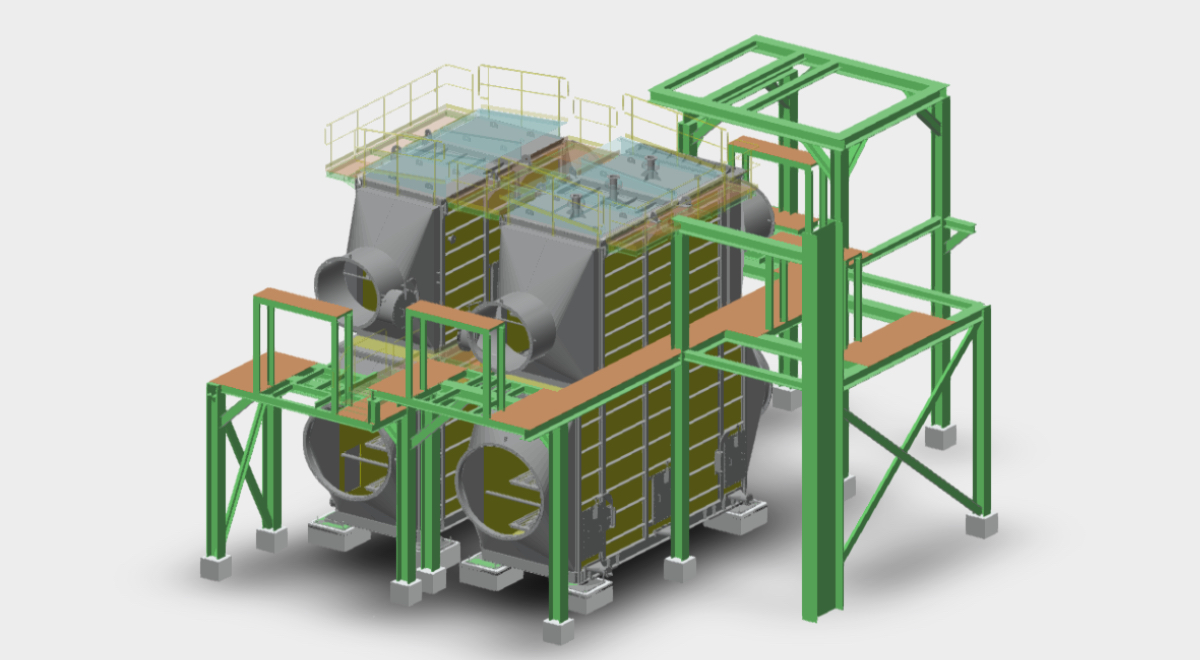

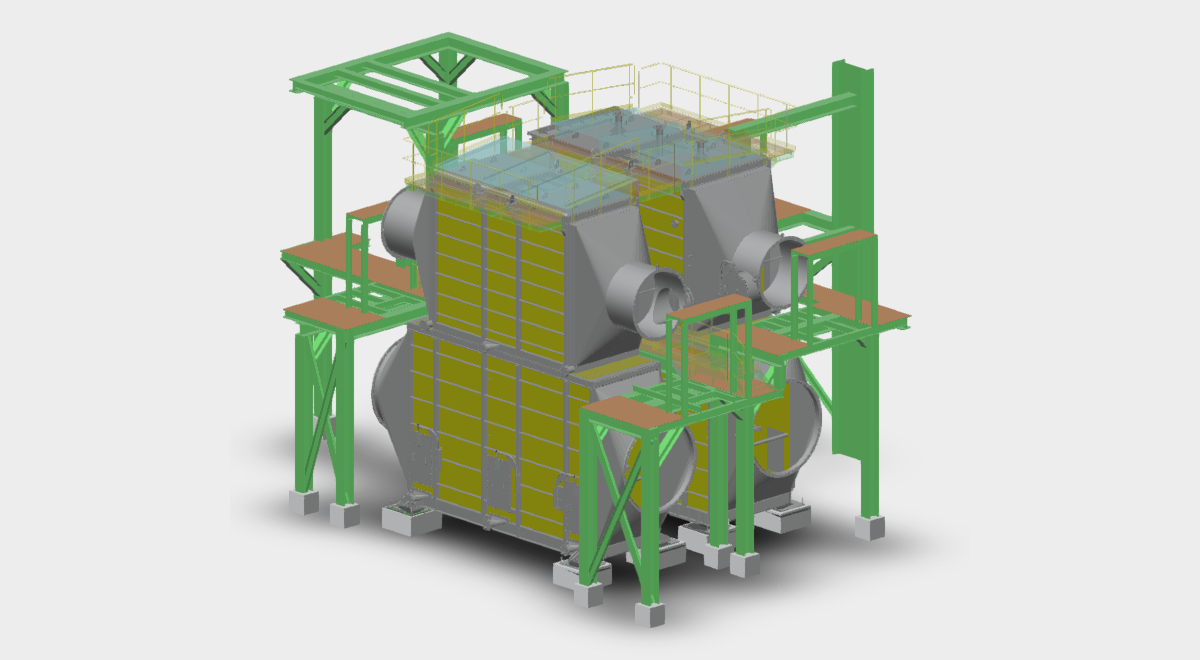

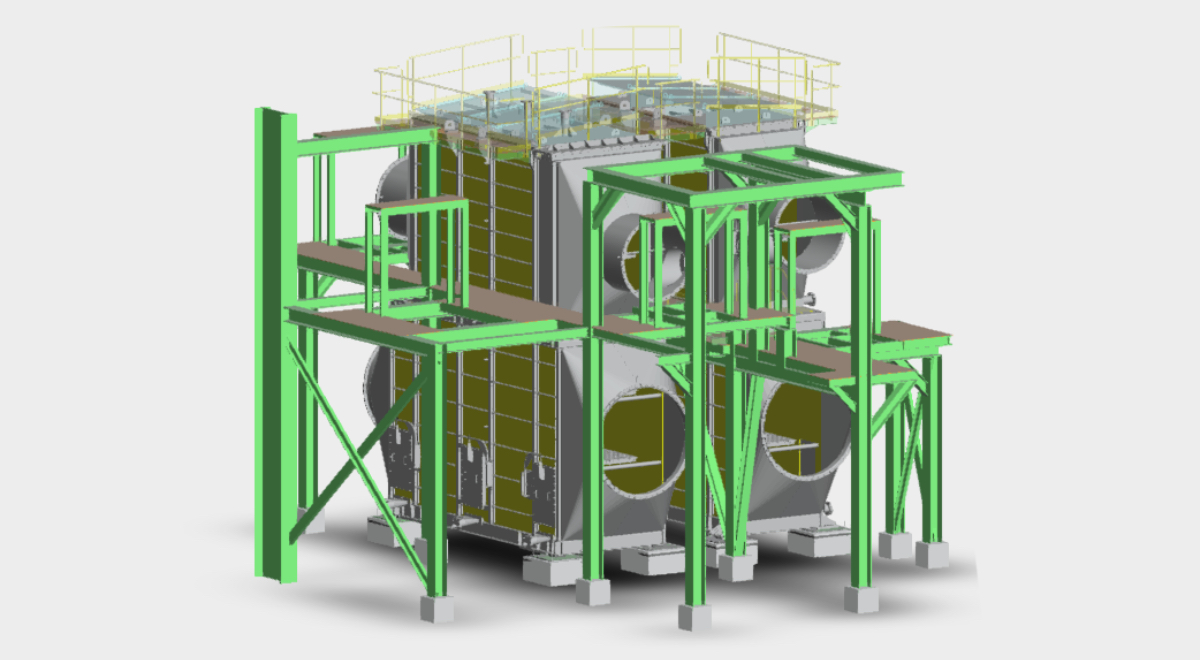

IVITAS provided workshop documentation for a two-chamber heat exchanger to heat combustion gas and air utilizing blast furnace flue gas. Our static calculation and optimization of the heat exchanger steel structure design respect the highest working temperature of flue gases (400 °C for up to 15 min.) and operating temperature of the blast furnace gas (240 °C max. at the highest working overpressure of 20 kPa).

The heat exchanger calculation was performed in SCIA Engineer on a spatial model using the finite element method. Analysis of the temperature field at the interface between the exchanger chambers was run in ANSYS Workbench software. Autodesk Inventor and AutoCAD were used for the processing of the model and workshop documentation delivery.

Client: ForSTEEL

Location: Trinecke zelezarny, Czech Republic

Implementation: 2020

Software used: Autodesk Inventor, AutoCAD, SciaEngineer, ANSYS Workbench